Offers more than just high-quality components—it delivers over a century of manufacturing excellence and engineering innovation. As a trusted British company with an unrivalled wealth of experience, Pegler provides customers with the broadest range of products and integrated solutions from a single, reliable supplier. Backed by industry-leading systems and customer support, Pegler Valves ensures performance, efficiency, and confidence in every project.

-

Sector Leading Health & Safety Control

-

Environmental Governance ISO14001

-

ISO 9001 Quality Management Systems

-

Embedded Corporate Social Responsibility

Pegler ResiFlow System:

The Prefabricated Utility Array

WHY CHOOSE PEGLER RESIFLOW SYSTEM

Key Functions & Components

-

Isolation: Provides isolation for the individual dwelling, allowing easy maintenance without affecting the primary system. Features inlet and outlet isolation valves with extended quarter turn T-handles.

-

Pressure Reduction: Includes a built-in PRV cartridge with an integral strainer, adjustable between 1.5 bar and 6 bar, ensuring pressure is maintained at the required reduced level for optimal performance within the apartment. The PRV is "Creep-Free" in accordance with BS EN 1567.

-

Maintenance Access: Provides access to gauge and meter visibility. Includes drain points for maintenance or water treatment dosing. Features accessible, replaceable built-in check valves for backflow protection.

-

Metering: Offers a capped water meter connection and a direct fitting concentric style Class D water meter connection, positioned after the outlet stop valve to comply with water authority policy.

ADVANTAGES:

-

Simplified Maintenance: The combined unit simplifies maintenance for each individual apartment, ensuring easy access, safety, comfort, and minimum downtime.

-

Optimised Performance: Maintains system operating requirements through pressure reduction and protects against backflow.

-

High Quality Materials: Manufactured using hygienic copper alloys CW511 and CC768S.

-

Certifications: WRAS and UK Reg4 approved.

Technical Snapshot (ResiFlow RES1 & RES2):

-

Available in ¾” and 1” threaded connections (BSPF), with optional VSH Tectite and VSH XPress adapted connections.

-

PN16 rated.

-

Maximum temperature rating of 80⁰ C.

-

Includes a custom moulded EPP insulation system that is removable for service, high performance, and recyclable.

-

Features pressure gauges before and after the PRV.

-

Ideal for branched potable water systems in multi-occupancy buildings.

APPLICATIONS:

VALVES

A Comprehensive Range of Valves for Building Services & Commercial Needs

Pegler offers a comprehensive valve portfolio suitable for a wide range of commercial and residential applications, including Potable, Heating, and Cooling systems. Our optimally designed valves provide reliable isolation and control.

-

Ideal for situations where a slim profile, low weight isolation and throttling are required on DN65 and above pipe sizes.

-

Available Sizes: DN65 – DN600 size range.

-

Materials: Ductile Iron construction with Stainless steel disc as standard.

-

Operation: Lever and gearbox operation options available; Gearbox driven above DN200.

-

Rating: PN16 rated.

-

Options: Fully lugged and semi-lugged options available.

-

Certification: NSF Reg4 Approved as stated.

-

Warranty: Covered by a 5-year warranty.

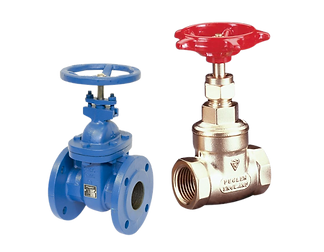

GATE VALVE

-

Ideal for isolating a range of fluids in pipelines. Traditional full way design.

-

Available Sizes: DN15 – DN300 size range.

-

Materials: Brass, DZR, Bronze, and Cast-Iron construction materials available.

-

Connections: Choice of push-fit, press-fit, threaded, compression and flanged connections.

-

Ratings: PN16, PN20 rated.

-

Certification: Reg4 approved where stated, Kite Marked where required.

-

Authenticity: Pegler provides features to verify the authenticity of your Pegler Gate Valve, such as matching markings, handle characteristics (shade, spokes, W number), rating disc details, surface finish, connection shape, and body ejector marks. Laser marked QR codes offer traceability and security.

PRESSURE REDUCING VALVE

-

Function: Allow high system pressures to be adjusted to protect downstream equipment and pipelines.

-

Available Sizes: ½” (DN15) to 4” (DN100 size range).

-

Connection: Screwed female connection.

-

Inlet Temperature: Maximum inlet temperature 80°C.

-

Outlet Pressure: Adjustable between 0.5 bar and 6 bar.

-

Finish: Nickle plated brass finish.

-

Rating: PN25 rated.

-

Certification: NSF Reg4 Approved.

VHS CONNECTION

Push-Fit & Press-Fit Fittings

Complementing our valve range, Pegler offers the VSH Tectite (Push Fit) and VSH Xpress/Sudo-Press/PowerPress (Press Fit) fittings, providing fast, reliable, and secure connection solutions.

VSH TECTILE (PUSH FIT)

-

Sizes 15mm – 54mm across various ranges (Classic, Sprint, Pro, 316 Stainless).

-

Rated up to 16 bar

-

Up to 114°C depending on the range.

VSH TECTILE (PUSH FIT)

-

Sizes DN15 up to DN108.

-

Max 16 Bar working pressure, Temperature Range -20°C to 110°C.

-

Various approvals including BSI Kitemark (BS 8537:2010), DVGW, KIWA, WRAS, etc.

-

95% recyclable.

VSH POWERPRESS (PRESS FIT)

-

For Schedule Pipe (EN and ASTM standards).

-

Epoxy Coated and Nickel plated.

-

16 bar pressure across the range, 150⁰C Peak.

-

Applications include HVAC, Gas, Fire and Compressed Air.

About Aalberts Integrated Piping System

Innovation & Quality

Quality takes a balanced approach consisting of people and processes with the right tools for every job. at “Aalberts”, everyone owns quality at the source. we don’t make, pass, or accept quality defects. Unlike those who see quality as an end-protector of product integrity, we design and manufacture for high performance, a proactive approach to quality that endures.

Award-Winning Innovation and British Manufacturing.

Innovation is central to Pegler's approach. We received a special innovation award for our static and dynamic balancing valves (Apollo ProFlow Type 1600 Dynamic Balancing Valve - PICV) at the NORDBAT trade fair in Lille, designed to eliminate problems in heating and cooling systems.

Manufacturing Excellence: Pegler Valves are manufactured in Doncaster, UK, utilising the latest techniques and materials. Our end-to-end process ensures continuity of British manufacturing, guaranteeing the highest level of reliability and quality. All elements, from design to expert production, ensure accuracy, flexibility, and system efficiency.

brand synonymous with quality

Standards & Compliance

Commitment to Quality and Compliance

Pegler products are compliant with relevant standards and hold important certifications, including WRAS, UK Reg4/NSF Reg4, BSI Kitemark, DVGW, KIWA, UL, Sintef, Sitak, and adhere to standards such as BS EN 1567, BS EN 806, BS 8537:2010, EN 10220, EN 10225, and ASTM standards. This demonstrates our commitment to quality, safety, and performance.